Photogravure stands as one of the most significant printing methods in philatelic history. This detailed printing process, which utilises microscopic cells etched into copper, has been instrumental in producing high-quality stamps since the 1930s.

The Technical Process of Photogravure

Photogravure is fundamentally a photomechanical process combining elements of photography and intaglio printing. The process involves several precise steps:

- A copper cylinder receives a coating of light-sensitive gelatine

- The cylinder is exposed to UV light through a film positive

- The gelatine hardens proportionally to light exposure

- Acid etching creates cells of varying depths

- These cells hold different amounts of ink during printing

Technical Specifications

- Image resolution: up to 25,000 dots per square inch

- Standard print density: 150–300 lines per inch

- Continuous tone capability Photographic reproduction quality

Historical Implementation

The British Post Office Adoption (1934)

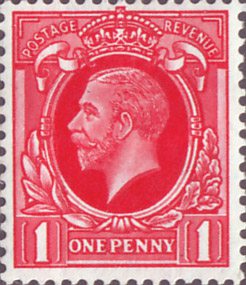

The introduction of photogravure for British definitive stamps in 1934 marked a significant technical advancement. The Photography Centenary issue of 1939 particularly demonstrated the method’s capabilities in reproducing photographic images. The 1934 George V definitive series was printed by Waterlow & Sons Ltd using photogravure, showcasing the technique’s suitability for large-scale stamp production.

Notable European Applications

Netherlands

The Dutch postal service began using photogravure in 1941 for their definitives. Queen Wilhelmina – 1940-1947 – Type ‘Konijnenburg’ demonstrates excellent examples of photogravure printing, showing the technique’s ability to reproduce fine detail and subtle shading.

Belgium

The 1949-1950 Belgian definitives featuring King Leopold III were produced using photogravure, exemplifying the technique’s capability for portraiture. These stamps show particularly fine gradations in skin tones and fabric details.

Switzerland

This famous Swiss charity stamp series used photogravure from 1928 onward. These stamps often depicted local flora, fauna, and historical figures, making them visually rich and detailed. The photogravure process was ideal for capturing the intricate designs and fine tonal gradations in these intricate images, making them stand out in the world of philately.

Technical Advantages and Limitations

Advantages

- Consistent reproduction of photographic images

- Reliable quality across extended print runs

- Superior detail retention

- Effective security features

Limitations

- Higher initial setup costs

- Slower production speed compared to offset printing

- Specialised equipment requirements

- Cost-inefficient for small print runs

Modern Applications

Contemporary stamp production often employs photogravure for:

- High-value denominations

- Commemorative issues

- Security-sensitive printings

- Specialist collections

Identification Methods

Collectors and researchers can reliably identify photogravure-printed stamps through several distinctive characteristics. The most immediate indicator is the subtle relief of the printed ink on the stamp’s surface; photogravure typically produces a slightly raised ink surface that can be felt with gentle handling. When examining tonal gradients, one should observe smooth, continuous transitions between light and dark areas, particularly noticeable in portraits or landscape designs.

Under magnification, photogravure stamps reveal a characteristic screen pattern—a regular arrangement of minute cells that hold the ink. This pattern differs from the line structures found in intaglio printing or the rosette patterns typical of offset lithography.

Finally, solid areas of colour in photogravure prints exhibit a distinctive depth and uniformity, though they may show the fine screen pattern under magnification. These identifying features, when considered together, allow for confident authentication of photogravure printing methods.

Technical Significance

Photogravure’s importance in stamp production derives from several interconnected technical attributes. The process enables precise reproduction capabilities that consistently capture fine detail and subtle tonal variations, particularly important for portraiture and complex designs.

The method provides consistent print quality across long production runs, making it suitable for definitive stamp issues that require millions of identical copies. Additionally, the durability of the printing surface—the etched copper cylinder—ensures that quality remains stable throughout the print run, with minimal degradation of the image.

The process also incorporates inherent security features through its distinctive screening pattern and ink laydown characteristics, making stamps more difficult to counterfeit. These technical attributes, combined with photogravure’s ability to handle both photographic imagery and line work, have secured its position as a significant method in postal stamp production.

If you are interested in different types of printing techniques for stamps, you might also like:

33 year old casual stamp collector from the UK!