Lithography is a printing technique where an image is drawn on a flat, smooth surface (traditionally a limestone plate) using a greasy medium. The plate is then chemically treated so that the drawn areas attract ink while the blank areas repel it. When paper is pressed against the inked plate, the image transfers, creating a precise, high-quality print. For postage stamps, this method allows for detailed, consistent reproduction of intricate designs and text.

Postage stamps may be small, but they represent a fascinating intersection of art, technology, and postal history. Today, we’re exploring one of the most significant printing methods in philatelic history: lithography. This revolutionary technique has shaped stamp production for over 170 years and continues to evolve in the modern era.

Origins and Basic Principles

At its core, lithography exploits a simple chemical principle that most of us learn when we are young, oil and water don’t mix. This fundamental concept, when applied to printing, creates a method that’s both elegant and effective.

Traditional lithographic printing begins with a flat surface, historically limestone (hence “litho” from the Greek word for stone). The artist or printer draws the design using a greasy material – either special crayon or ink. This is where the magic begins. When the stone is moistened, water clings to the blank areas but is repelled by the greasy design. When oil-based ink is applied, the opposite occurs – the ink sticks to the design but is repelled by the wet areas. The result? A perfect transfer of the image to paper.

Historical Development in Stamp Production

The philatelic world first embraced lithography in Bavaria in 1849. This wasn’t just a minor development – it represented a significant shift in how stamps could be produced. The technique offered several advantages over existing methods:

- Cost-effectiveness for larger print runs

- Ability to create more detailed designs

- Potential for multicolour printing

- Relatively quick production time

Early Stone Lithography

The earliest lithographed stamps were produced using limestone blocks, a practice that continued well into the 19th century. These stones needed to be:

- Perfectly flat

- Finely grained

- Free from any imperfections

- Thick enough to withstand pressure

- Large enough to print multiple stamps at once

The process was labor-intensive but produced remarkable results. Master printers would carefully prepare the stone’s surface, ensuring it was perfectly level and had the right texture to hold both water and the greasy design material.

Characteristics of Lithographed Stamps

Lithographed stamps have distinct characteristics that collectors and philatelists learn to recognize:

Visual Features

- Softer, less defined lines compared to engraved stamps

- Flatter appearance of colours

- Subtle gradations possible in tonal values

- Less dimensional appearance than intaglio printing

- Sometimes visible dots under magnification (in modern offset lithography)

Evolution of the Technology

The progression of lithographic techniques in stamp printing mirrors the broader evolution of printing technology:

Stone to Metal

The transition from limestone to metal plates marked a significant advancement:

- Zinc plates, introduced in the late 19th century

- Aluminium plates became standard in the 20th century

- Metal plates were lighter, more durable, and easier to store

- Multiple plates could be created from a single master design

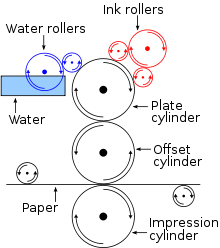

Offset Lithography

The introduction of offset printing revolutionized stamp production:

- Design transfers from plate to rubber blanket to paper

- Allows for higher-speed printing

- Better detail reproduction

- More consistent quality across print runs

Modern Photolithography

Today’s stamp production often utilizes sophisticated photolithographic processes:

- Computer-to-plate technology

- High-precision colour separation

- Integration with digital design tools

- Enhanced security features

Notable Examples in Philatelic History

Several historic stamps showcase the capabilities of lithographic printing:

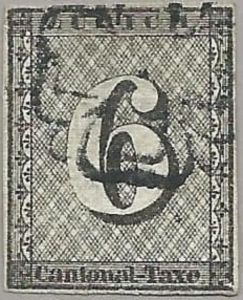

The Zürich 4 and 6 (1843): Early examples of lithographed stamps, showing remarkable detail for their time. The Plane over the sculptured oxcart from Uruguay is also a nice example.

Many British colonial stamps showed how lithography could be used for large-scale production

Quality Considerations

- More susceptible to smudging than engraved stamps

- Colours can be more vibrant but potentially less stable

- Print quality highly dependent on proper ink/water balance

- May show wear more quickly in high-volume printing

Security and Modern Applications

Modern stamp production has evolved into a sophisticated blend of artistic design and security measures. While lithography remains at the core of many stamp printing processes, it rarely stands alone. Instead, postal authorities and security printers employ a hybrid approach that combines multiple printing methods. Lithography typically handles the background colours and designs, creating rich, vibrant foundations for each stamp.

This is often complemented by intaglio printing for the primary design elements, adding both security and tactile depth to the final product. The combination isn’t just about aesthetics – it creates multiple layers of security that make counterfeiting significantly more difficult. Additional security features might include specialized inks, microprinting, and other anti-counterfeiting measures that are integrated seamlessly into the design.

Digital Integration

The digital revolution hasn’t bypassed stamp production – if anything, it’s enhanced the capabilities of lithographic printing in remarkable ways. Contemporary stamp production seamlessly merges traditional printing expertise with cutting-edge digital technology. Computer-aided design allows for unprecedented precision and creativity in stamp artwork, while sophisticated colour management systems ensure consistency across entire print runs.

Quality control has been transformed by automation, with computer systems monitoring every aspect of the printing process in real-time. Perhaps most impressively, modern systems can incorporate variable data printing, allowing for unique elements to be added to individual stamps while maintaining the efficiency of mass production.

If you’re interested in the different ways stamps are printed, have a look at these posts:

- What is Offset Printing

- What is Photogravure

- An Introduction to Typography

- What is Intaglio Printing

33 year old casual stamp collector from the UK!